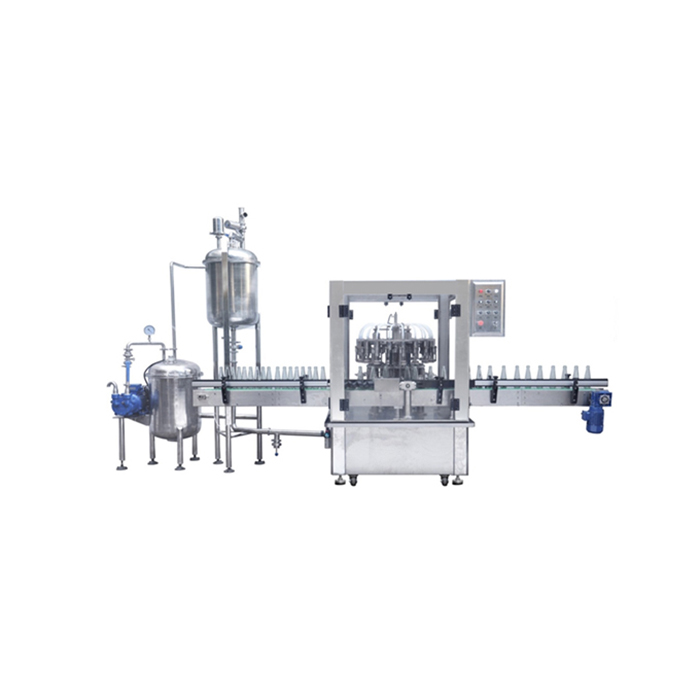

Улаан лоолийн сүмс эргэдэг дүүргэлт бөглөх машин

Our factory has been expert at filling packing machines near 10 years with rich expereince, welcome to visit our factory at any time. ( working time. )

This machine is automatic detect bottle (no bottle no filling), filling, automatic fall rubber plug (no bottle, no capping), automatic out of the bottle and some other functions. Compared with other congeneric filling machine, this machine running stable, low noise, high yield, convenient maintenance, safe and stable. It’s most ideal medicine bottle filling machine, Fully meet the requirements of GMP. For special bottle filling materials, our company can design and manufacture. This filling machine is automatic feed bottle, bottle detect, filling, cover rubber plug and outside capping.

Техникийн үзүүлэлтүүд

Дүүргэлтийн хэмжээ: 5-100 мл (өөрчилж болно)

Үйлдвэрлэлийн хүчин чадал: 30-60 шил / мин

Резинэн залгуурыг хучиж байна: ≥99%

бөглөх хэмжээ нарийвчлал: ≥99%

Эрчим хүч: 1кВт

Хүчдэл: 110/220 / 380В

Давтамж: 50 / 60HZ

Жин: 550 кг

Хүргэлтийн нөхцөл

1. Before delivery,machine must be tested and photoed(with or without the packaging),also video

2. After photo and video sent,the balance payment will be asked to pay,our factory will delivery machine on the seconds of full payment arrived to our account.

3. Buyer are warmly welcome to inspect the manufacturing of machine.

Техникийн дэмжлэг

1. Sales person online service from 8:00 am to 10:00 pm .

2. Engineer can be arranged for readjusting and installing at the buyer's factoroy,but relative fees should be born by the buyer

Хамтын ажиллагааны брэндүүд

Schneider, Siemens, Mitsubishi, AirTAC, SICK, Omron, Panasonic гэх мэт.

Түргэн мэдээлэл

Төрөл: Бөглөх машин

Нөхцөл: Шинэ

Програм: Ундаа, химийн, түүхий эдийн, хоол хүнс, эмнэлгийн

Сав баглаа боодлын төрөл: Сав

Сав баглаа боодлын материал: Шил, металл, хуванцар

Автомат зэрэг: Автомат

Жолоодлогын төрөл: Механик, Цахилгаан, Пневматик

Хүчдэл: 110/220 / 380В

Эрчим хүч: 1кВт

Гарал үүслийн газар: Шанхай, Хятад (Эх газрын)

Брэндийн нэр: VKPAK

Хэмжээ (L * W * H): 2000 * 1500 * 1700 мм

Жин: 550

Гэрчилгээ: CE ISO9001

Борлуулалтын дараах үйлчилгээ үзүүлсэн: Гадаадад техникийн үйлчилгээ үзүүлэх боломжтой инженерүүд

Зүйл: Улаан лоолийн сүмс эргэлт дүүргэх машин

Үйлчилгээ: Боловсролтой

Чанар: Guranteed

Үнэ: Өрсөлдөх чадвартай

Гүйцэтгэл: Маш сайн

Засвар үйлчилгээний түвшин: Бага

Бүтэц: Ротари

Хавхлагын толгойг бөглөх: 1 эсвэл бусад

Бөглөх материал: Шингэн оо

Хүрээ: Зэвэрдэггүй ган

A Tomato Sauce Rotary Filling Capping Machine is a specialized piece of equipment designed to fill and cap bottles with tomato sauce automatically. This type of machine is commonly used in food processing plants and factories that produce large quantities of tomato sauce.

The filling and capping process is done by a rotating carousel that holds the bottles in place as they move through each station. At the first station, the bottles are filled with tomato sauce using a series of nozzles that control the flow of sauce into the bottle. The machine is designed to fill the bottles accurately, ensuring that each bottle is filled to the correct level.

After the bottles are filled, they move to the capping station where they are sealed with a cap. The machine uses a variety of mechanisms to apply and tighten the caps onto the bottles, including screw capping, snap capping, or twist-off capping.

Tomato sauce rotary filling capping machines come in a variety of sizes and configurations, depending on the production needs of the manufacturer. Some machines can fill and cap hundreds of bottles per minute, while others are designed for smaller batch sizes.

Overall, a tomato sauce rotary filling capping machine is an essential piece of equipment for any food processing plant that produces large quantities of tomato sauce. It is an efficient and reliable way to ensure that each bottle is filled and capped accurately, helping to improve the quality and consistency of the final product.